Hello

and welcome to a new blog post. Today I present to you selected properties of

natural fiber based polymer compounds as part of our design data for plastic

engineering series.

Which

natural fibers can be used and why to replace e-glass with them?

The

use of natural fibers represents a sustainable alternative to synthetic glass

and carbon fibers. They can be used in applications ranging from automotive,

aeronautics to building and construction. Natural fibers can be plant, animal,

and mineral based. In this post, we focus only on plant based fibers as

reinforcement. The most important plant based fibers (cellulose) include

cotton, flax, hemp, jute, pineapple, abaca, wood, wheat, rice, bamboo, and

esparto. Among the animal fibers are lamb’s wool, goat hair, angora wool, and

cashmere. Mineral fibers are fibrous brucite and wollastonite.

Recycling

of glass and carbon fibers is still high energy consuming. Table 1 shows the

environmental parameters (production of 1 kg of fibers [5]) of hemp and glass

fibers. In all three categories, hemp fibers represent a sustainable

alternative to glass fibers.

|

| Table 1: environmental parameters (production of 1 kg of fibers [5]) of hemp and glass fibers |

Properties

of fibers

Before

deciding to replace glass fibers with natural fibers, a look at the mechanical

properties of natural fibers is important. This will later enable a better

material formulation and material selection.

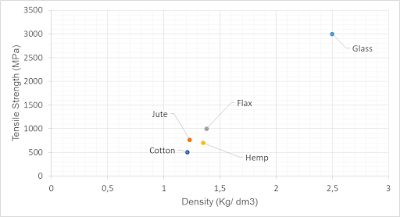

Figure

1 and 2 compares the mechanical properties of glass with those of jute, flax,

hemp, and cotton. It can be shown that the tensile modulus of flex and hamp is

with 70 GPa in the range of the glass tensile modulus.

|

| Figure 1: Tensile strength vs. density of different natural fibers and glass fiber |

|

| Figure 2: Tensile modulus vs. density of different natural fibers and glass fiber |

For

formulating plastic compounds using natural fibers, thermal processing

properties must be in the suitable range of the fibers. Polyethylene (PE) and

Polypropylene (PP) base polymers are good examples for such a suitability and

our examples will be based on a PP copolymer.

Figure

3 presents the mechanical properties of PP based natural fiber compounds (six

different fibers; always 35%) and compares them to a PP based glass fiber

compound (also 35%). Within the natural fiber compounds, mechanical values are

in a similar range. PP glass fiber reinforced compounds are double in tensile

modulus and tensile strength.

|

| Figure 3: Tensile modulus vs. tensile strength of different PP compounds with natural fiber reinforcement and PP with glass fiber reinforcement |

Conclusions

Natural

fiber based compounds allow a weight saving in the range of 10 -30%. Most used

fibers are hemp, jute, and flax. Hemp fiber production is almost pesticide

free. Additionally, hemp fibers are hydrophilic and proper drying must be done

prior to compounding. In terms of performance, natural fiber compounds can be

used in automotive interior applications (door panels, seat backs paneling),

together with exterior applications (bumpers, spoilers). In building and

construction, such compounds can be found in roof panels and insulations.

Thanks

for reading and #findoutaboutplastics

Herwig

Juster

Interested to talk with me about your plastic selection, sustainability, and part design needs - here you can contact me

Literature:

[1]

WIS Polymer-Wissenmatrix; https://www.advanced-compounding.com/de/polywood-pp.html

[3] https://www.frontiersin.org/articles/10.3389/fmats.2019.00226/full#B95

[4] https://hal.archives-ouvertes.fr/hal-03153829/document

[5]

Shahzad, 2011: https://journals.sagepub.com/doi/10.1177/0021998311413623

No comments:

Post a Comment