Hello and welcome to part 3 of our bio-based Polyamide series.

Check out part 1: PA 5.6 and 5T (Chemical Structure, Production, Properties, Applications, Value Proposition) here and part 2: Short and Long Chain Aliphatic Polyamides (PA 6, PA 11, PA 6.10, PA 10.10) here.

In this post, I focus on three topics under the sustainability umbrella: bio sourcing, LCA, and certifications

Bio sourcing for polyamides

Materials based partially or complete on renewable biomass fall into this definition. Castor beans, trees, and crops are major examples of this category. Fossil based or biomass based materials have all carbon atoms in their back. This allows a distinction of bio-based polyamides in terms of their bio content. For functional groups and inorganic groups, this is not possible and a mass-based approach is used.

ASTM D6866 and EN 16640 are used for the determination of bio-based carbon content in polyamides and other polymers. Base working principle is the radiocarbon analysis which allows to determine the carbon fraction (C14 measurement) [1].

Life Cycle Assessments

Life Cycle Assessments (LCAs) are used to identify the environmental impact of a certain material or produced good thorough their life cycle and currently two major standards are used for LCAs: ISO 14040:2006 (Environmental management — Life cycle assessment — Principles and framework) and ISO 14044:2006 (Environmental management — Life cycle assessment — Requirements and guidelines).

The structure of a LCA contains a scope section and the impact categories. Within the scope section distinctions between three variations is done: gate-to-gate, cradle-to-gate, and cradle-to-grave. For polymers the preferred scope is cradle-to-gate and this scope covers all processes as well as environmental impacts (buying feedstock and making the polymer). Often high performance bio-polyamides are tailored to the specific customer requirements by compounding selected additives into the base polymer. End-of-life disposal is more complex and harder to access for the polymer manufacturer. Environmental impact can be estimated using following metrics:

-greenhouse gas emissions,

-ozone depletion,

-human toxicity (cancer effects),

-human toxicity (non-cancer effects),

-photochemical ozone formation,

-ionizing radiation, particulate matter,

-terrestrial acidification,

-terrestrial eutrophication,

-marine eutrophication,

-ecosystem toxicity,

-resource depletion (fossil),

-resource depletion (abiotic),

- and water resource depletion.

For customers and polymer manufacturers, the global warming potential (GWP expressed over CO2 equivalent) is the most interesting value as well as the most frequently requested value within the LCA report.

Example Polyamide 6.10

Manufacturing of a long chain Polyamide PA 6.10 is made as shown in Table 1 by sebacic acid (C10H18O4) and HMDA (C6H16N2). For bio-based Polyamide 6.10, the sebacic acid is bio-sourced. In general, bio-sourced products have a lower carbon footprint since they contain locked atmospheric (biogenic) carbon in the product. In case of combustion or degradation of sebacic acid (based on castor oil) at the end-of-life, this would result in approximately 1.5 kg of CO2 equivalent release. The whole Polyamide 6.10 would lead to a release of 2.2 kg of CO2 equivalent. The total carbon footprint (from raw material, polycondensation of Polyamide minus the biogenic carbon of sebacic acid) of Polyamide 6.10 is 4.6 kg Co2/kg. In case Polyamide 6.10 is made 100% out of petrochemicals, the carbon footprint would be 7.3 kg CO2/kg. The aforementioned 2.2 kg of CO2 equivalent are most probably released before 100 years since end-of-life is reached before 100 years (GWP calculations use a 100 year time frame).

|

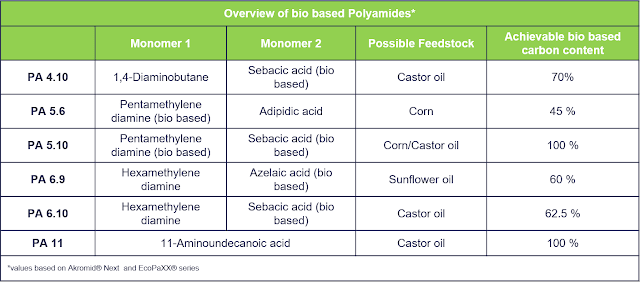

| Table 1: overview of bio based Polyamides |

Certifications

As already mentioned under the section “Bio-sourcing”, radiocarbon dating is a good method to distinguish between fossil based carbon and bio based carbon. The C14 isotopes for fossil based material display a different set compared to bio based ones. Standard is DIN ISO 10694. Other certifications are ISCC PLUS and REDcert². Both are leading sustainability certification systems for bio-based and recycled materials. Certifications and proper labeling get more and more important since the end customers are demanding such distinctions more and more.

What are some trends in 2022?

We see more and more the use of recycled plant based oils and fats to produce Polyamides which reach a carbon footprint of only 0.5 kg Co2/kg [2]. Also, 100% bio-based carbon content is possible with Polyamides. PA 11 uses only 11-aminoundecanoic acid which can be won from castor oil. This enables a 100% bio-based carbon content. Also PA 5.10 can be produced in a 100% bio based carbon way using pentamethylene diamine and sebacic acid out of corn and castor oil.

Thanks for reading and #findoutaboutplastics

Greetings,

Herwig

Interested to talk with me about your plastic selection, sustainability, and part design needs - here you can contact me

Literature:

[1] https://www.findoutaboutplastics.com/2021/07/biopolymers-difference-between-bio.html

[2] https://akro-plastic.com/compound-overview/akromid-next/

[3] Stephan Kabasci: Bio-Based Plastics: Materials and Applications

No comments:

Post a Comment