Hello and welcome to a new post. Today I show you how you can use the 3P (price, performance, and processing)-triangle to select engineering biopolymers.

An overall summary on bio-based polymers can be found in this three part bio-based polyamide series.

Motivation of Engineering Biopolymer Usage

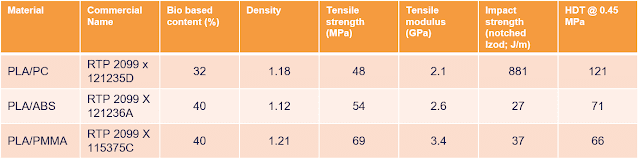

Engineering polymers represent much lower volumes compared to commodity plastics and bio-derived engineering polymers represent a niche within this engineering plastics segment. Packaging materials are much more visible to consumers on a daily basis compared to for example under the hood automotive applications. Therefore, research focus was more directed towards replacing high volume single use polymers with recycled and bio-based materials solutions. However, consumer perspective is shifting towards all different polymer applications to have recycled content or be bio-based. In addition, more and more OEMs demand recycling and bio-based content in their plastic parts. Material suppliers work on drop-in bio-based solutions for traditional polymer applications. One way are hybrid materials out of a 100% bio based polymer blended with a traditional engineering polymer such as PC (Table 1). Often biopolymers show a brittle behaviour. Blending a bio-copolyester such as Polybutylene adipate terephthalate (PBAT) with a Polylactic acid (PLA) will result in a ductile (derived from PBAT) and stiff (derived from PLA) material. Polyamides are among the most used engineering polymers and there are already several short- and long chain bio-based Polyamides available, where one or both monomers are derived from bio sources (Table 2).

|

| Table 1: hybrid materials out of a 100% bio based polymer blended with a traditional engineering polymer |

|

| Table 2: overview bio-based Polyamides |

Material Selection – Visual approach using the 3P-triangle

The price, processing and performance triangle allows to compare similar plastics and how well they measure up against each other in a visual way. Incorporation of environmental sustainability values is done over “processing” where the nature of feedstock is included and over “performance” which takes the materials impact during use-life and recycling phase.

With bio-based engineering polymers, the balance between fulfillment of rigorous property requirements of the target application and life-cycle impact need to be found during material selection. I developed three steps to achieve such a balance.

1. Step: We define the maximum allowed environmental impact of the material which can be provided by the customer (numerical value – example: GWP)

2. Step: Incorporate this value into the semi-quantitative polymer comparison triangle together with price, processing and performance.

3. Compare different polymers to each other and make a decision which to investigate further

Example: injection / blow moulded water bottle

In the following, an example helps to better understand the 3P-triangle approach. For an injection moulded water bottle, the incumbent material is most of the times PET and can be placed more towards the price vertex due to its low costs. As a next alternative, bio-based PET can be used which improves towards the processing vertex. PLA, on the other hand will improve processing, however will increase material costs. This may change in the future too, due to more availability of bio-based materials. Altogether, the 3P-triangle is a tool which can be put into your polymer material selection tool box and supports selecting bio-based polymers.

I made also a short training video on this topic:

Thanks for reading and #findoutaboutplastics

Greetings,

Herwig

Interested to talk with me about your plastic selection, sustainability, and part design needs - here you can contact me

Literature:

[1] Plastics and Sustainability: Towards a Peaceful Coexistence between Bio-based and Fossil Fuel-based Plastics, Michael Tolinski

No comments:

Post a Comment