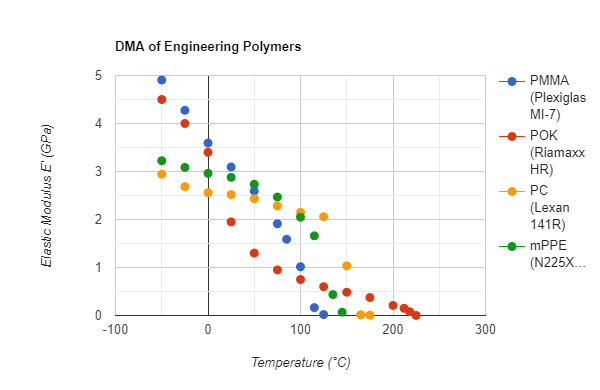

Hello and welcome to a new blog post in which we continue with the DMA data. Today we discuss reinforced engineering polymers (pls. find here the DMA data of neat resin, and here of high performance polymers). Here you can find the collection of all my posts on design properties for plastics engineering - engineering and high performance polymers.

Reinforcement such as glass fibers can increase thermal and mechanical properties of amorphous and semi-crystalline thermoplastics.

Example Polyamide 6 (PA 6): neat vs. reinforced polymer

Figure 1 [1] shows an unreinforced Polyamide 6 which has a glass transition temperature of 65°C and a heat deflection temperature (HDT) of 65°C at 1.82 MPa. It can be shown that the modulus declines from 2.81 GPa (pre- Tg) to 0.56 GPa (post-Tg), resulting in a decrease of 80%.

In the next step we add 14% glass fiber as reinforcements. This amount of glass fibers increases the HDT from 65°C to 200°C at 1.82 MPa. Also, modulus is almost doubled and the decline from pre- to post-Tg is 55% (from 4.46 GPa to 1.98 GPa).

In the last step we add 33% glass fiber reinforcements. In this final case, HDT can be slightly increased to 210°C at 1.82 MPa. However, modulus can be increased to 7.87 GPa and the decline is now below 50% (from 7.87 GPa to 3.99 GPa).

|

| Figure 1: DMA results of an unreinforced Polyamide 6 and glass fiber reinforced Polyamide 6. |

DMA of reinforced engineering polymers (PBT, PA, PC and POK)

Figure 2 shows the elastic modulus of glass fiber reinforced PBT-GF30 (Valox® 420; SABIC), PC-GF20 (Lexan® 3412; SABIC), PA 6-GF30 (Ultramid® B3EG6; BASF), and POK-GF30 (RIAMAXX® HR; RIA-Polymers).

PBT-GF30 and PA 6-GF30 have a similar elastic modulus behavior over the temperature range. Polyketone with glass fiber reinforcement is superior at lower temperatures, however above room temperature the behavior is similar to Polycarbonate. At higher temperatures (above 150°C), Polyketone is similar to reinforced PA 6 and PBT.

|

| Figure 2: Elastic modulus of glass fiber reinforced PBT-GF30 (Valox 420; SABIC), PC-GF20 (Lexan 3412; SABIC), PA6-GF30 (Ultramid B3EG6; BASF), and POK-GF30 (RIAMAXX® HR; RIA-Polymers). |

Herwig Juster

Interested to talk with me about your polymer material selection, sustainability, and part design needs - here you can contact me

Interested in my monthly blog posts – then subscribe here and receive my high performance polymers knowledge matrix.