Hello and welcome to a new post. Today I present to you dynamic mechanical analysis (DMA) data of most used unfilled engineering polymers.

In a previous post we discussed the storage modulus vs. temperature behavior of different high performance amorphous and semicrystalline polymers. Also how DMA can be used as a polymer material selection tool. Here you can find the collection of all my posts on design properties for plastics engineering - engineering and high performance polymers.

In general, the DMA is a thermo-analytical method that estimates the viscoelastic properties of a given material over the course of different temperatures. It steps away from a single point view toward a multipoint data view which is beneficial for polymer material selection tasks.

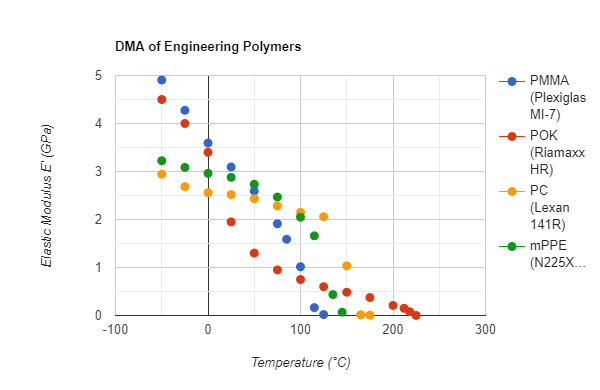

Figure 1 shows the elastic modulus of ABS, POM, PBT, and PA 6.6 and Figure 2 shows it for PMMA, POK, PC, and mPPE. Figure 3 contains all polymers in a single chart.

|

| Figure 1: Elastic modulus of ABS, POM, PBT, and PA 6.6 (all unfilled) |

|

| Figure 2: Elastic modulus of PMMA, POK,PC, and mPPE (all unfilled) |

|

| Figure 3: Elastic Modulus of ABS, POM, PBT, PA 6.6, PMMA, POK, PC, and mPPE. |

Thanks for reading and #findoutaboutplastics

Greetings,

Herwig

Interested to talk with me about your polymer material selection, sustainability, and part design needs - here you can contact me

Interested in my monthly blog posts – then subscribe here and receive my high performance polymers knowledge matrix.

Literature:

[1] M. Sepe: Dynamic Mechanical Analysis for Plastics Engineering, Elsevier

[2] https://www.findoutaboutplastics.com/2020/07/design-properties-for-engineers-dynamic.html

[3] https://www.findoutaboutplastics.com/2018/12/dynamic-mechanical-analysis-dma-as.html

No comments:

Post a Comment