Hello and welcome to a new blog post. Today we discuss briefly the major benefits of plastics for our environment and society. In this post I selected nine impact factors which are in my view important and the list of benefits of plastics not only for the environment is much longer.

|

| Major Benefits of Plastics for the Environment And Society |

The following video shows a brief summary:

1) Durability: polymer based pipes are designed to last for more than 100 years. Also they reduce the overall failure rate and ensure fresh water supply to many difficult reachable regions of the world. Additionally, PET plastic bottles make drinking water available in hard accessible parts of the world, and can be recycled after use.

2) Water saver: as we mentioned water before, the production of a plastic bag consumes less than 4% of the water needed to make a paper bag.

3) Light weighting: lightweight plastic parts save around 3,000 liters of fuel over the lifetime of an average car.

4) Food waste prevention: plastics packaging increases the shelf life. In the case of bananas, wrapping them in a modified atmosphere bag extends their shelf-life by 2 to 3 days.

5) Product protection: plastics packaging helps to reduce the products which are sold loose. It has been found that this in-store waste in some cases leads to losses of 20%.

6) Resourceful in production: producing plastics uses only 4%-6% of the world's oil production. The remaining 94%-96% are used for transport, energy, heat or are burnt. We will discuss this in detail further below.

7) Recyclability: thermoplastics can be recycled however it is not always technically or economically possible. In general, recycling one tonne of plastic bottles saves 1.5 tonnes of Carbon emission.

8) Reduction of CO2 emissions: it is shown by several studies that plastics reduce CO2 emissions massively and fossil fuel use massively.

9) Safety: chemicals and additives in plastics are strictly regulated, tested for decades. In most cases they are only present in parts per million amounts.

Furthermore, following characteristics ensuring that polymers are a highly competitive class of materials and will lead to additional growth:

10) Creating complex shapes by using moulding techniques: using injection moulding, thermoplastics, rubbers, and thermosets can be formed into complex 3D shapes. The amount of parts can be reduced by integrating functions too.

11) Chemical resistance and biological inertness: plastic packaging is used to safely use chemicals such as bleach, lubricant oils, solvents, and acids. Using plastics for food packaging and medical applications is enables due to the biological internets of polymers.

12) Electrical and thermal insulators: electrical hardware is safe to use since plastic due not conduct electricity (by adding certain fillers they can be made conductive). The low thermal conductivity of polymers is used in foams for isolation of housing

13) Practical sustainability example from the plastics industry - "Using only as much material as is needed to ensure functionality".

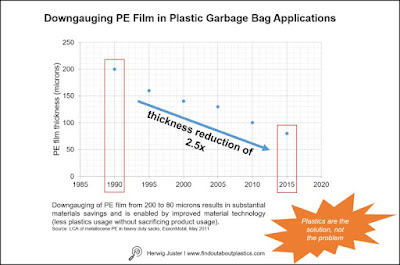

Downgauging of PE film from 200 to 80 microns results in substantial materials savings (Figure 1) and is enabled by improved material technology (less plastics usage without sacrificing product usage).

|

| Figure 1: Practical sustainability example - downgauging of PE film from 200 to 80 microns results in substantial materials savings [5]. |

14) Practical sustainability example from plastics industry: replacing plastic packaging materials with other packaging materials, which have the same functionality results in a doubling in life cycle energy consumption and even a tripling in life cycle greenhouse emissions in the EU (Figure 2).

|

| Figure 2: Practical sustainability example from plastics industry: replacing plastic packaging materials with other packaging materials will lead to increased emissions [6]. |

15) Practical sustainability examples from plastics industry: replacing hydraulic with all-electric injection moulding machines (Figure 3).

Compared to all-hydraulic machines, all-electric injection moulding machines are

-less expensive to operate,

-quieter,

-produce more consistent parts,

-allow fewer rejections

- and are cleaner since they do not use oil.

Energy reduction of all-electric injection moulding machines ranges between 30% to 60% compared to hydraulic machines. A study [7] found that the savings could be achieved across many materials such as Polycarbonate and Polystyrene. Furthermore, energy saving are achieved even if the cycle time stays the same as required for the hydraulic injection moulding machine. Typical recorded savings for a medical product (inhaler) is 58% and with an automotive component (connector) 62%. The best is to combine all-electric machines and optimize the cycle time of the moulding operation.

Additionally, by using servo-hydraulic injection moulding machines, almost 50% of energy demand can be saved too and they represent a good compromise.

|

| Figure 3: Saving energy by replacing hydraulic with all-electric injection moulding machines [7]. |

.png) |

| Figure 4: The role of plastic products in the total carbon footprint of consumers [8]. |

17) Practical sustainability examples from plastics industry: embodied energy of commodity plastics

Embodied Energy is refereed to the energy directly or indirectly used in the creation of a unit mass and the estimation consists out of process energy, transportation, and energy of material resources.

The infographic below (Figure 5) compares the embodied energy of commodity and engineering polymers, together with metals.

In general, the estimates for commodity plastics is between 75-100 GJ/metric ton of resin manufactured. If additives and fillers are added, the cradle-to-gate value will change.

Comparing the embodied energy of plastics to other materials, it can be seen that plastics are in a similar range as Copper and Zinc, except for Titanium, Aluminum, Magnesium, and Chrome Steel. This makes metal replacement with plastics attractive: reducing weight by having a lower density and reducing the environmental footprint too.

|

| Figure 5: Comparison of the embodied energy of commodity and engineering polymers, together with metals. |

18) Thermal insulation of houses - Expandable polystyrene (EPS) and extruded polystyrene (XPS)

Most of us are familiar with the material of expandable polystyrene (EPS), commercially available under the brand Styropor [10]. Polystyrene (PS) uses styrene as a monomer which is derived from benzene. Since it provides excellent thermal insulation properties as a foam it is used in many applications such as thermal insulation plates for building and roofing, refrigerators and freezers, and industrial cold storage facilities.

The usage of 5 cm thick EPS insulation plates is already enough to reduce the heating effort of your house by half, resulting in saving around 1000 liters of oil per year which represents 2800 tons of CO2 emissions. Comparing the insulation effect of different construction materials, it can be shown that a 2 cm EPS layer has the same insulation effect as a 46 cm solid brick or 120 cm solid concrete (Figure 6).

.png) |

| Figure 6: Insulation performance of different building materials - 2 cm of EPS have the same effect as 120 cm of solid concrete [10]. |

19) Plastics are reducing waste

It takes between 1.3kg to 1.8 kg of other material to replace 0.5 kg of plastic [11]. For packaging sector, this impact is shown above at Nr. 14.

20) Plastics composites in aircraft construction: the usage of cabron-fiber reinforced composites in modern aircrafts such as the Airbus A-350 and Boeing B787 Dreamliner (uses approx. 50% plastics composites), lead to a reduction in weight and this translates to a 30% fuel saving.

21) Plastics demand is not growing exponentially - their growth rate is between 3%-4%: Mr. Julian Allwood showed in his book "Sustainable Materials – With Both Eyes Open (2011) [12]" the global demand for the five key materials (Cement, Steel, Paper, Aluminum, and Thermoplastics) since 1960. It can be seen that all materials grow at the same rate of 3%-4% a year.

22) Plastics are not a major source for Greenhouse gas emissions: In 2019, OECD estimated the Greenhouse gas emissions from plastic with 1.8 billion tons (1.6 billion tons from production and conversion; end-of-life: 193 million tons). Therefore, plastics were only responsible for around 3.3% of global emissions, which are around 54.6 billion tons of CO2eq [13].

23) After reading all the data on plastics, there might be still the following question coming up: "Do I use too much plastic products and harm the environment?", the short answer is no and here is why:

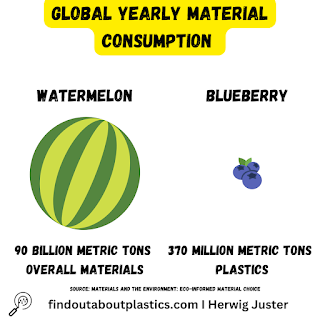

The answer was well researched by independent scientist Dr. Chris DeArmitt and he presented literature which shows that plastics (mainly PE, PP, PVC, and PET) only account for 1% by volume (0.4% by weight) of society’s material use. Ceramics (mainly concrete) represent 84%, natural materials like wood 9%, and metals 6%. Global plastics consumption is around 370 million metric tons per year, however this is still small compared to the 90 billion metric tons of overall materials used [14, 15]. In order to put things better into perspective, we can compare the overall amount of materials used to a watermelon and compare it to a blueberry, representing the yearly plastics consumption (Figure 7).

|

| Figure 6: Watermelon vs blueberry - comparing the overall material consumption to the plastics consumption (on a yearly basis) [14]. |

24) Plastics & oil consumption: For producing plastics in Europe, it is estimated that 4%-6% of oil and gas is needed. Transport, electricity and heating sectors are taking up 87% of oil and gas which is simply burnt and therefore lost [15].

Additionally to this fact, other sources of oil use are decreased by plastics. By lowering the weight of automobiles, airplanes, ships, packing, and goods, they cut down on fuel use and CO2 emissions. After the manufacturing and production stages, a product uses 80% of its energy.

Products produced of plastic require a lot less energy to produce than those made of other materials. The lifecycle energy consumption of these products would increase by about 57% and the greenhouse gas emissions would increase by 61% if plastics were replaced with alternatives.

Therefore, oil and gas are way too precious to burn them, it is better to make high performance materials, such as polymers, out of them.

Altogether we can state that plastics are part of our solution and are not the problem.

I published already several posts on how polymer impacting the environment in a positive way:

Turning thermoplastics carbon neutral

Global warming potential vs thermal properties of thermoplastics

Sustainability in plastics industry

Eco profiles of polymer resins

Thanks for reading and #findoutaboutplastics

Greetings

Herwig Juster

Interested in my monthly blog posts – then subscribe here and receive my high performance polymers knowledge matrix.

!NEW! Ultra and High Performance Polymer Selection - new online course coming soon - join the waiting list

Literature:

[1] https://www.linkedin.com/today/author/mark-stewart-md-pb?trk=author-info__article-link

[2] https://plasticsparadox.com/

[4] A. Andrady - Plastics and Environmental Sustainability

No comments:

Post a Comment