|

| Polymer Material Selection - Example water pipes for plumbing (Herwig Juster) |

Hello and welcome to this new blog post with the topic of polymer material selection. In this post we cover the material selection of water plumbing pipes as an example of the building and construction market. For the selection we will apply my developed Polymer Funnel Method (in detail explained here and in this video).

Figure 1 presents the four different stages of the material selection funnel and this overview serves us as a guideline.

|

| Figure 1: Polymer Selection Funnel with its four stages. |

What are the top 5+ plastics used in building and construction?

Most used plastics in building and construction are polyvinyl chloride (PVC), high density polyethylene (HDPE), expanded polystyrene (EPS), polyurethane (PU), polycarbonate (PC) and polymethyl methacrylate (PMMA). PVC is used for window frames and floorings, HDPE for tubing and piping, EPS and PU for outside and inside insulation. PC and PMMA is used for transparent sheeting applications applied for example at carports.

Benefits of using plastics in construction are that they are lightweight, energy efficient, quick and safe installation compared to other materials, cost effective and high resistance to UV and fire.

Polymer material selection for water plumbing pipes

Let us get started with the funnel.

Funnel stage 1: Material selection factors

In Funnel stage 1 we assess the water supply piping requirements. We have to consider the three legs of the Environmental Stress Cracking (ESC)-triangle:

- Environment including temperature rating: inhouse mounting; no exposure to UV-light and no special weatherability conditions are needed; temperature of water is up to 80 °C.

- Stress: mainly the fluid pressure and the pipe is fixed (no permanent bending movement);

- Chemicals and chemical compatibility: water and chlorinated water

- Agency ratings: EU 10/2011; NSF/ANSI 51

- Space layout: limited; flexibility of piping is needed,

- Function: transport drinking water (hot and cold) from heating station inside the house to different sanitary locations within the house;

- Lasting: 50 years life span

- Costs: medium cost range since volume is on high end;

- Recyclability: must be given at end of life

Table 1 summarizes the important requirement information (requirement worksheet).

|

| Table 1: requirement worksheet of Funnel stage 1. |

Funnel stage 2: Decision on thermoplastic or thermoset

Since flexibility is needed for mourning the pipes in confined space thermoplastic solutions are preferred. Apart from the already discussed thermoplastics used in plumbing, there are two major types of thermosetting pipes: 1) reinforced plastic mortar (RPM) pipe and (2) reinforced thermosetting resin (RTR) pipe. Together with glass fiber reinforcement such pipes show high strength, however they cannot be melted and reformed again.

In our example, thermoplastics are preferred due to easier forming and mounting, as well as high regulatory fulfillment for drinking water.

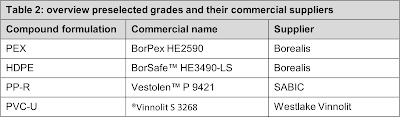

We pre-selected:

- BorPex HE2590 (PEX)

- BorSafe™ HE3490-LS (HDPE)

- Vestolen™ P 9421 (PP-R)

- Vinnolit® S 3268 (PVC-U)

Table 2 summarizes the pre-selected thermoplastics and its details which will be used for the detailed selection discussion in Funnel stage 3.

|

| Table 2: overview pre-selected thermoplastics. |

Funnel stage 3: Selection discussion with worksheet (qualitative matrix analysis)

Funnel stage 3 represents with the qualitative matrix analysis the major element for the selection discussion. Table 3 summarizes the outcome of this process. In the first step we rank how good each material can fulfill the requirements (0 to 5=best) and then we assign priorities to each of the requirements (0 to 5 = highest priority). In the last step we multiply the requirement fulfillment with the priority and add the values up.

In our case PP-R (score: 99 points) and PEX (score: 97 points) have the highest rank and both materials should be evaluated in Funnel stage 4.

|

| Table 3: result of the qualitative matrix analysis. |

Funnel stage 4: Testing, selection of material and vendor

We reached the final phase of the Polymer Selection Funnel where we test and further evaluate our findings from Funnel stage 3.

Both PEX and HDPE are suitable for usage in our application case, however PEX is due to its cross-linking not as easy for recycling as HDPE. However, this is changing too, since chemical recycling of PEX waste makes promising steps. Therefore, recycling challenges will be no limitation.

Check out here another polymer material selection example (baby bottles).

Thanks for reading and #findoutaboutplastics

Greetings Herwig

Interested to talk with me about your polymer material selection, sustainability, and part design needs - here you can contact me

*NEW* my Polymer Material Selection book is available for purchase here *NEW*

Interested in my monthly blog posts – then subscribe here and receive my high performance polymers knowledge matrix.

Literature:

https://www.acplasticsinc.com/informationcenter/r/applications-of-plastic-construction-materials

https://www.freshwatersystems.com/blogs/blog/types-of-plastic-water-pipe

https://www.globalspec.com/learnmore/flow_control_fluid_transfer/pipe_tubing_hose_accessories/plastic_pipe

https://healthybuilding.net/blog/585-what-to-know-when-selecting-water-pipes

https://www.thespruce.com/basic-types-of-plumbing-pipes-1822487

https://www.acplasticsinc.com/informationcenter/r/common-plastic-building-materials

https://theconstructor.org/building/plastics-construction-material/12438/

https://pvc4pipes.com/pvc-pipes/pvc-pipe-categories/#:~:text=Unplasticised%20PVC%20is%20also%20known,PVC%2DU%20have%20many%20benefits.

https://www.globalspec.com/reference/54714/203279/polyethylene-pe-pipes

https://www.globalspec.com/reference/54717/203279/thermoset-plastic-pipe

https://www.borealisgroup.com/news/neste-borealis-uponor-wastewise-group-enable-chemical-recycling-of-hard-to-recycle-plastic-waste-into-new-high-quality-plastic-pipes