Hello and welcome to this blog post. Today we discuss the tensile stress and strain data of selected thermoplastics as a function of temperature.

Why are multi-point data important in polymer material selection and part design?

Multipoint data of different polymer and polymer compound properties prevail information which would otherwise may be overlooked during material selection and product design. Most property data shown on technical data sheets are single-point values at failure level. Most of the time only a single temperature is covered (room temperature). This is useful for comparing different material data sheets however for part design it has its limitations. Multipoint data help to think in time-dependency and temperature-dependency behaviors. Graphically such behaviors can be better accessed. Single point data can lead to misjudgment.

Stress-strain curves of thermoplastics as function of temperature

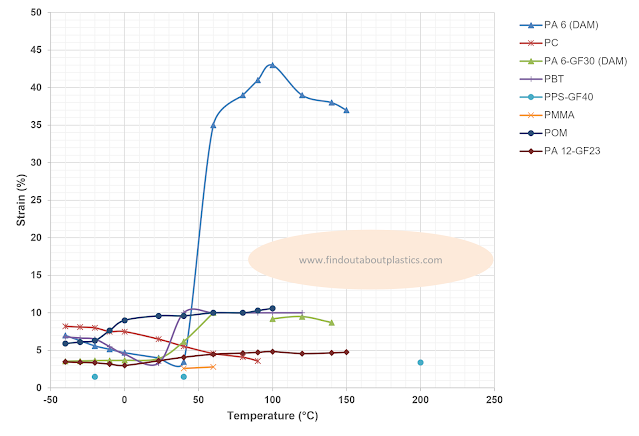

In Figure 1 the results of stress experiments and in Figure 2 the strain results of different amorphous and semi-crystalline plastics are shown. Following grades were analyzed:

PBT: Ultradur® B 2550 FC

PA 6-GF30: Ultramid® B3EG6

PC: Makrolon® 2205

PA 6: Ultramid® B3K

PMMA: PLEXIGLAS® 6N

PPS-GF40: TEDUR L 9107-1

POM: Ultraform® H4320 Q600

PA 12-GF23: VESTAMID® L1833

|

| Figure 1: Stress vs. temperature of thermoplastics |

|

| Figure 2: Strain vs. temperature of thermoplastics |

Through the increase in temperature, mobility of the polymer chains is increasing and some brittle polymers turn into more tougher polymers allowing them to withstand certain loads.

Conclusions

DMA and stress-strain curves used combined are an efficient way to explore part application properties at use temperature.

Check out here more multipoint data

Interested to talk with me about your polymer material selection, sustainability, and part design needs - here you can contact me

*NEW* my Polymer Material Selection book is available for purchase here *NEW*

Interested in my monthly blog posts – then subscribe here and receive my high performance polymers knowledge matrix.

Literature:

https://www.campusplastics.com/campus/en/datasheet/Ultradur%C2%AE+B+2550+FC/BASF/20/128f11a1/SI?pos=3

https://www.campusplastics.com/campus/en/datasheet/Ultramid%C2%AE+B3EG6/BASF/20/3675d41d

https://www.campusplastics.com/campus/en/datasheet/Makrolon%C2%AE+2205/Covestro/22/9b29274b/SI?pos=10

https://www.campusplastics.com/campus/en/datasheet/Ultramid%C2%AE+B3K/BASF/20/3a22f000

https://www.campusplastics.com/campus/en/datasheet/PLEXIGLAS%C2%AE+6N/R%C3%B6hm/21/2d5df2ec/SI?pos=2

https://www.campusplastics.com/campus/en/datasheet/TEDUR+L+9107-1/MOCOM/5/91e531bc/SI?pos=1

https://www.campusplastics.com/campus/en/datasheet/Ultraform%C2%AE+H4320+Q600/BASF/20/2ebf4379/SI?pos=8

https://www.campusplastics.com/campus/en/datasheet/VESTAMID%C2%AE+L1833/Evonik+Operations+GmbH/66/f991fc87/SI?pos=12

No comments:

Post a Comment