|

| Polymer Material Selection Example - Yoga Mats |

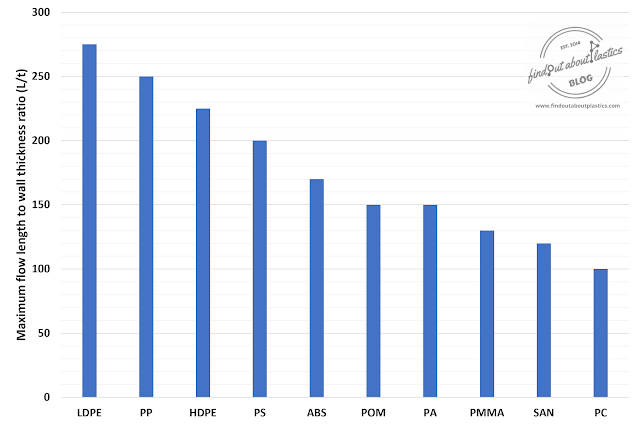

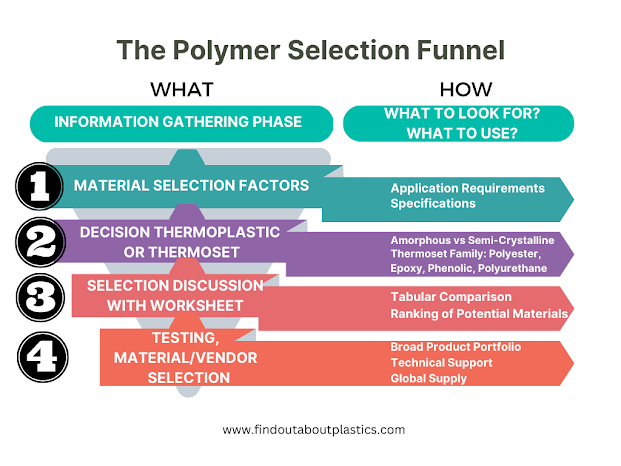

Hello and welcome to another polymer materials selection example using the Polymer Funnel methodology. In this post we discuss the material selection of the optimal material for Yoga mats. Figure 1 presents the four different stages of the material selection funnel and this overview serves us as a guideline.

|

| Figure 1: The four different stages of the polymer material selection funnel. |

Global sporting goods market

The global sporting goods market is a billion dollar industry and can be split into the following sections:

- athletic footwear

- exercise equipment

- licensed sports merchandise

- and athletic apparel.

Sports clothes use plastic fibres such as Polyamide, Polyester, Acrylic, Lycra, and Spandex which make this segment leading in the use of polymers. Sports shoes use ethyl vinyl acetate (EVA) for the mid-sole to provide lightweight cushioning. Extra comfort for the insoles is provided by polyester foam padding. We see more and more recycling plastics used for shoes too. Also for stadium seats recycled plastic bottles can be used. Millions of recycled plastic bottles were used to make 6,700 seats for the Maracanã stadium at the Rio 2016 Olympics.

Polymer material selection for Yoga mats

Figure 2 shows a standard exercising Yoga mat which can be found in stores already. We will select the optimal material for such a mat.

|

| Figure 2: Standard Yoga mat in green. |

Funnel stage 1: Material selection factors

In Funnel stage 1 we assess the yoga mat requirements and turn them into material selection factors:

- Keeping thickness level of 4 mm (6 mm depending on type) over time

- Lightweighting, considering different densities of materials (min. Density of 0.38 g/cm3)

- Balance of comfort and stability

- Length of min 180 cm

- Good surface texture

- Hardness between Shore A 40 and 60

- Colorability

- Eco-friendly (no harm to environment)

- No allergic reactions to skin and easy cleaning

- Price level

Table 1 summarizes the important requirement information with quantitative and qualitative values (requirement worksheet).

|

| Table 1: Summary of important requirements and information of the Yoga mat project. |

Funnel stage 2: Decision on thermoplastic or thermoset

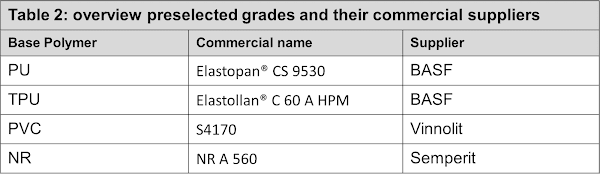

In Funnel stage 2 we decide between the thermoplastic and thermoset material route. Since we need soft surfaces together with cushion, thermoplastics are the preferred selection path. Additionally we consider rubber materials too. Proposed materials are Polyurethane (PU), Polyvinyl Chloride (PVC), Thermoplastic Urethane (TPU), and Natural Rubber (NR):

-Elastopan CS 9530 (PU)

-Elastollan® C 60 A HPM (TPU Shore A 60)

-Vinnolit S4170 (PVC)

-NR A 560 (NR, Semperit Shore A 40)

Table 2 summarises the preselected polymers.

|

| Table 2: Summary of pre-selected polymers. |

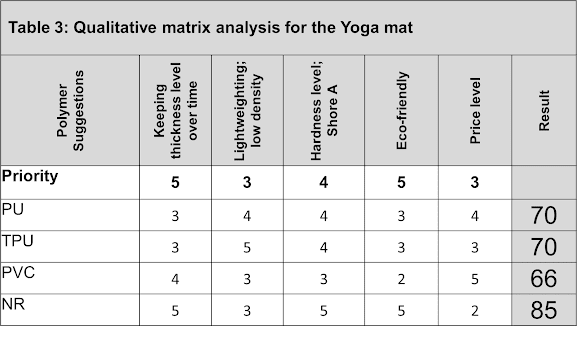

Funnel stage 3: Selection discussion with worksheet (qualitative matrix analysis)

In the third funnel stage we use the qualitative matrix analysis methodology to assess the suitability of the pre-selected polymers (Table 3). For starting, we insert the material selection factors from Table 1 in the top upper line and assign each a priority number (ranging from 0= low to 5= high priority). This is followed by adding the pre-selected materials. Now we rank each material how good it can fulfil the requirements listed in the top layer (5 = perfectly fulfilled). In the end we multiply the priority number of each requirement with the fulfilment number and add them up to a total sum. On the right side of Table 3 the results are listed. In our case, NR has the highest number (85), followed by TPU and PU (both 70), and PVC (66). NR offers a good balanced density, haptic level, and is made from natural materials. TPU combines certain properties of NR and PVC and stands in the middle. The cheapest and more sticky solution for Yoga mats is PVC. For further mechanical testing, NR, TPU, and PU are considered.

|

| Table 3: Results of the qualitative matrix analysis for the Yoga mat material selection. |

Funnel stage 4: Testing, selection of material and vendor

Now mechanical, chemical and other specific tests are done based on prototype mats. Auch tests can include potential customers too to receive their feedback if they feel comfortable with one of the materials. In the case of Yoga mats it is feasible to use 1-2 different materials since the customer preferences can be different. Some prefer natural based materials and others like the TPU and TPE based Yoga mats.

Check out other polymer material selection examples:

Polymer Material Selection Funnel Example - Baby Bottles (Consumer Packing Example)

Thanks for reading and #findoutaboutplastics

Greetings

Herwig

Interested to talk with me about your polymer material selection, sustainability, and part design needs - here you can contact me

Interested in my monthly blog posts – then subscribe here and receive my high performance polymers knowledge matrix.

Literature:

[1] https://branded.disruptsports.com/blogs/blog/tpe-vs-pvc-vs-rubber

[2] https://www.statista.com/topics/961/sporting-goods/

[3] https://www.plasticsmakeitpossible.com/about-plastics/wait-thats-plastic-sports-edition/#:~:text=Nylon%2C%20polyester%2C%20acrylic%2C%20lycra,%2C%20comfy%2C%20sweat%20wicking%20fabrics.

[4] https://plasticseurope.org/plastics-explained/plastics-in-use/sport-leisure/#:~:text=Plastics%20in%20sports%20footwear&text=For%20comfort%20and%20support%2C%20the,extra%20comfort%20on%20the%20insoles.

[5] https://branded.disruptsports.com/blogs/blog/tpe-vs-pvc-vs-rubber