Hello and welcome to this new Rule of Thumb post. Today we discuss the thin wall injection moulding of engineering polymers.

High performance polymers such as PPS and LCP reach low viscosity levels at high injection moulding shear rates and temperatures. Other polymers such as Polycarbonate and Polymethyl methacrylate have a high melt viscosity, however flow properties can be improved by adding additives.

Thin wall injection moulding with engineering polymers

The common wall thickness of engineering plastics ranges between 2 to 4 mm. Thin wall moulding focuses more on wall thickness below 2 mm. In general, the wall thickness influences the stiffness of the part, achievable flow lengths in the mould, cycle times, shrinkage, and weight of the part. Thin wall injection moulding results in high shear rates and injection pressures too. Drivers for thin wall parts are the Electric & Electronics, Automotive, and Telecommunication industries.

How can we classify thin wall moulding in a quantitative way?

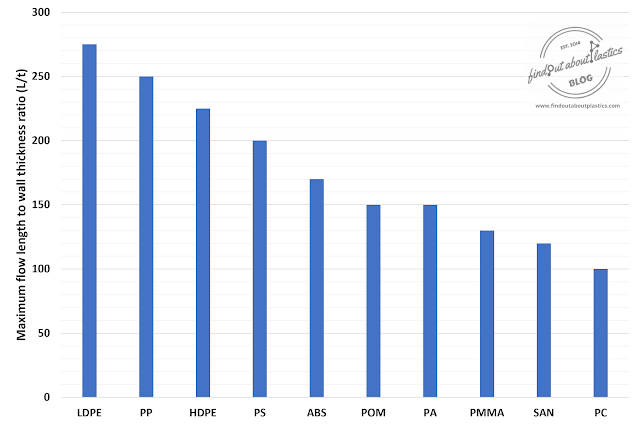

Spiral flow data is one way and is a good alternative to melt flow index (MFI) measurements. Another way of classification is over the flow length to wall thickness ratio (L/t). Since each polymer has different flow properties, the maximum achievable L/t ratios vary. Figure 1 shows the L/t ratio of commodity and engineering polymers based on a 2 mm wall section. Polyolefins, Polystyrenes, and ABS are good candidates for parts with 2 mm wall thickness and below.

|

| Figure 1: Maximum L/t of commodity and engineering polymers based on a 2 mm wall section. |

More Rule of Thumb posts can be found here.

Thanks for reading and #findoutaboutplastics

Greetings

Herwig Juster

Interested to talk with me about your polymer material selection, sustainability, and part design needs - here you can contact me

Interested in my monthly blog posts – then subscribe here and receive my high performance polymers knowledge matrix.

Literature:

[1] https://mastip.com/media/4274/thin-wall-moulding.pdf

[2] DuPont Design Guide

No comments:

Post a Comment