Hello and welcome to a new blog post in which we discuss recycling considerations for plastics part design.

Overview on recycling methods

To gain a better understanding of the topic of recycling, we first have a look at the six different recycling methods.

1. Product reuse: designers aim for usage of the product more than once. An example are returnable bottles.

2. Traditional disposal methods: in this case the product is dumped to landfill sites. It is not an optimal scenario for plastics, except for biodegradable plastics. Plastic landfilling is already forbidden in most European countries due to rising costs and public opinion.

3. Treatment and dumping: in this case, plastics are pre-treated and all dangerous pollutants are removed before dumping.

4. Mechanical recycling: the process of mechanical plastics recycling consists of collecting, sorting, cleaning and reprocessing into plastics pellets which can be used for new products (upcycling or downcycling).

5. Feedstock recycling: breaking down the polymers into monomers which then can be in turn polymerized again or used for other purposes.

6. Energy recovery: burning plastics to recover their stored energy. This is a good option for low-values mixes and soiled wastes. In general, plastics have a higher calorific value than coal.

Where to start with Design for Recyclability?

There are three actions which can be followed for first successes [3] - i call them the 1/3/longer actions:

1. Focus on one material for all parts of your application, creating a mono-material solution.

2. Simplify sorting and recycling by using only three different polymers (f.e. PE, PP, and PET) and use the correct part marking code.

3. Enhance durability of the materials in order to be more often recycled.

Plastic part marking codes

In past years, plastic part designers considered the part styling, safety, and cost efficiency as major points to pay attention to. Additionally, we now have the usage of low carbon footprint materials, together with the objective to enable easy recycling after end usage.

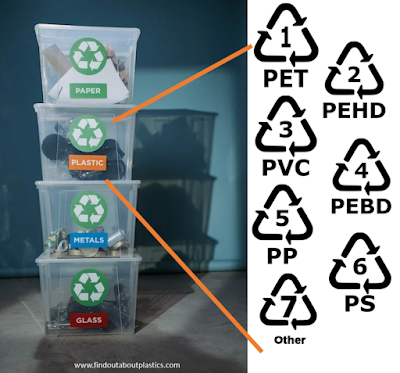

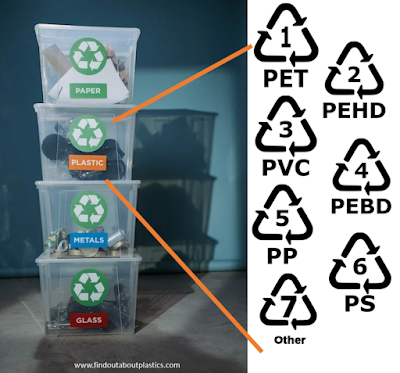

Enabler for proper recycling is the need to identify the plastics used in the part at the end of product life. Mixing different plastics makes it harder for mechanical recycling methods. Therefore, part marking standards were established. In the lead of this is the SPI resin identification code, which represents chasing-arrows with a number from 1 to 7 (Figure 1):

1=PET

2=HDPE

3=PVC

4=LDPE

5=PP

6=PS

7=Other

|

| Figure 2: SPI resin identification codes for commodity plastics |

This system is good for packing applications with commodity plastics such as LDPE and PP. However, since most of us deal with engineering parts, there are some more part marking codes which we can use.

For example, there is the ISO 1043 which consists out of four parts and covers the base polymers, fillers, additives, flame retardant, and plasticizers. Figure 2 shows an example of using this part marking standard. More examples can be found here.

|

| Figrue 2: Part marking example of a Polyamide 6 with glass fbers and flame retardant |

Supporting this topic, I made a miniguide (download here), and detailed blog post (here) allowing to deep-dive into the basics.

Conclusions

Using such part marking standards allows for easier collecting of used parts and creating post industrial recycled (PIR) materials as well as post consumer recycled materials (PCR).

Thanks for reading & #findoutaboutplastics

Greetings,

Herwig

Literature:

[1] https://www.iso.org/standard/50590.html

[2] Tangram Plastics Design Guide

[3] The Plastics Paradox - Chris De Armitt