Hello and welcome to another polymer material selection example using the Polymer Funnel methodology.

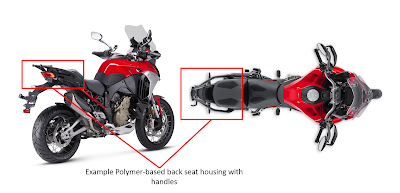

In this post we discuss the selection of a back seat housing for motorbikes (exterior component). Figure 1 presents the four different stages of the material selection funnel and this overview serves us as a guideline. Figure 2 shows the example of a polymer based backseat housing with handles of a motorbike.

|

| Figure 1: Polymer Selection Funnel with its four stages. |

In general, what are some structural materials for exterior automotive applications?

Structural and semi-structural exterior components need to fulfil stringent requirements and aliphatic (PA 6, PA 6.6, PA6.10)- as well as semi-aromatic Polyamides such as PPA and PARA (MXD6) play an important role as materials for such parts. Polyesters such as PBT can be found in various semi-structural exterior applications too (e.g. mirror mounting brackets).

|

| Figure 2: Example of the polymer-based back seat housing with handles. |

Polymer material selection for exterior structural back seat housing- selecting the optimal plastic material

Funnel stage 1: Material selection factors

Central objective of Funnel stage 1 is the assessment of the requirements which needs to be fulfilled by the motorbike back seat housing material:

-Stiffness and strength (Young’s modulus min. 20 GPa at room temperature)

-No need of painting the part; it must be ready to be used after injection moulding

-it must have a metal-like haptic effect

-processing via injection moulding must be easy (good flow) and thicker sections must be possible too.

-UV-stability over the part life time

Now we can turn requirements into material selection factors and continue with stage 2. Table 1 summarises the important requirement information (requirement worksheet).

|

| Table 1: Requirement worksheet of Funnel stage 1. |

Funnel stage 2: Decision on thermoplastic or thermoset

Analyzing the requirements leads us to the decision of continuing with the thermoplastic route over the thermoset route, since we need a stiff material with rigid properties. Among the thermoplastics, we have the option to select an amorphous polymer or a semi-crystalline polymer. Again, comparing the requirements, semi-crystalline polymers have very good stiffness and strength, good toughness and fatigue, low coefficient of friction making them suitable for applications exposed to heat, chemicals and wear. Such a material profile is needed in our application case.

After some research i found the following grades:

-PolyArylAmide (PARA-GF 50 wt%; UV-stabilized; Ixef® 1025; Solvay)

-PA 6.6-GF 60 wt% (AKROMID® A3 GF 60 1 black; Akro Compounds)

-PA66 + PA6I/6T GF 60 wt% (AKROLOY® PA GF 60; Akro Compounds)

Funnel stage 3: Selection discussion with worksheet (qualitative matrix analysis)

The core of the Polymer Selection Funnel is the qualitative matrix analysis where we rank how good each of the materials can fulfil the requirements from step 1 (0 to 5=best), followed by secondly, assigning priorities to each of the requirements (0 to 5 = highest priority). Finally a multiplication of the requirement fulfilment with the priority is done and the values are added up for each material.

Today I would like to introduce to you my new online POMS calculator which will make those steps for you. You can access the calculator over this link.

The result of the calculation can be seen in Figure 3. Ixef 1025 (PARA) reached 86 points, followed by AKROLOY® PA GF 60 (PA66 + PA6I/6T) with 68 points, and AKROMID® A3 GF 60 (PA 6.6) with 50 points. PARA offers high stiffness, low water uptake and the best surface appearance among all Polyamides. It is the combination of this unique property set which makes it the preferred choice for this application. If it would be an under -the-hood exterior application, the other two material options may be applied too.

|

| Table 3: Result of the qualitative matrix analysis using the new online POMS calculator. |

Funnel stage 4: Testing, selection of material and vendor

Now we have reached the testing and validating phase where we take the pre-selected grades from the outcome of Funnel step 3 and perform tests such as UV stability tests, endurance tests, as well as prototyping the part. Prototyping via semi-finished stock shapes or simple injection mould allows testing the different materials in the real application and drawing final conclusions. In our case, PARA could outperform the other materials in terms of surface appearance and metal-like haptics, which is favoured by the end-user.

More polymer material selection examples can be found in my "start here" section.

Thanks for reading and #findoutaboutplastics!

Greetings

Herwig Juster

Interested to talk with me about your polymer material selection, sustainability, and part design needs - here you can contact me

Interested in my monthly blog posts – then subscribe here and receive my high performance polymers knowledge matrix.

Literature:

[1] https://akro-plastic.com/productfilter/details/7723/

[2] https://www.solvay.com/en/brands/ixef-para

[3] https://www.solvay.com/en/brands/ixef-para/applications

[4] Polymer Material Selection: A practical guide on how to select polymers in a systematic way using the polymer material selection funnel method: https://www.amazon.com/-/de/dp/B0BSWM6BPD/ref=sr_1_1?__mk_de_DE=%C3%85M%C3%85%C5%BD%C3%95%C3%91&crid=2J7GJC06FKVU5&keywords=herwig+juster&qid=1695624594&sprefix=herwig+juste%2Caps%2C139&sr=8-1

No comments:

Post a Comment