Hello and welcome to this blog post on weather and UV resistant engineering polymers. I have split this post in three sections (overview styrene polymer family and PMMA; design data; material selection) and it should be supporting you in your next material selection project.

Short overview of the styrene polymers family (styrenics) and Polymethylmethacrylate (PMMA)

Polystyrene (PS) is widely known as material for packaging and consumer goods applications has a good hydrolysis behaviour, however has low performance when exposed to UV-light and weathering. It is an amorphous polymer and is fully transparent. Anti-UV agents and/or carbon black needs to be added in case it is used for exterior applications. Next to PS we have Styrene-acrylonitrile copolymer (SAN). Main impact is the amount of acrylonitrile. It can bes used between -20°C and 85°C, short time exposure till 95°C. It is a transparent polymer however it has a slight yellow impression. Therefore, soluble blue color is added to overcome this yellow appearance turning it into a slight bluish material. Adding glass-fibers to SAN will result in an engineering polymer (high stiffness, low shrinkage in-flow and cross-flow). In comparison to PS, SAN has a better weatherability performance which increases with the acrylonitrile amount. Downside is the rapid water uptake due to the polar nitrile group which makes proper drying before processing necessary. It is used in electrical engineering applications, automotive (lighting housing), and household goods.

PMMA

Polymethylmethacrylate (PMMA; known by its famous trade name “Plexiglas”) is an amorphous thermoplastic material with a glass transition temperature of 105°C. It is a stiff and hard polymer, however relatively brittle. It has very good optical properties (light transmission up to 92%). PMMA has a six time better impact behaviour compared to silicate glass making it a good choice for applications where transparency and stability is needed. It has very good weatherability and ageing properties. It can be used from -40°C up to +75°C, with a short term maximum temperature of 100°C.

Impact modified styrenics: ABS, ASA, and AES

Apart from PS and SAN, there is Acrylonitrile butadiene styrene (ABS). ABS is an amorphous polymer with a glass transition temperature of 105°C. It is made out of 3 different monomers: Acrylonitrile which provides heat resistance and chemical resistance to strong acids and bases; Butadiene which brings the good impact resistance as well as inferior low temperature resistance; and Styrene which allows ABS to be easily processed and gives it some rigidity. The impact resistance of ABS is around 5 to 10 times higher compared to PS. ABS can be used between -40°C and 85°C, with a short time peak temperature of 100°C. ABS has low resistance to weathering. Exchanging the butadiene rubber by ethylene propylene diene monomer (EPDM) rubber is an effective way to improve the weathering resistance of ABS. It is called acrylonitrile-(ethylene-propylene-diene)- styrene (AEPDS or AES). Also, using chlorinated polyethylene (PE-C) instead of butadiene has a similar effect. It is called acrylonitrile-(chlorinated polyethylene)-styrene (ACS). AES combines excellent weather resistance with low temperature resistance. It can be used for outdoor applications which are exposed to UV and impact. If we exchange the butadiene rubber of ABS with an acrylic rubber, we obtain Acrylonitrile-styrene-acrylate (ASA) which does not contain a double bond in the rubber part. This in turn increases the weatherability and ageing in an effective way. Combing meythlmethaacralyte with ABS will result in MABS which shows excellent impact resistance at low temperatures and have a good light transparency. However, due to the butadiene rubber it is not suitable for outside applications (double bond in rubber).

Check out my review post on ABS here (incl. Youtube video) and here my short video on "ABS vs. ASA vs. AES".

Figure 1 shows the polymer performance pyramid and the location of PS, SAN, ABS and PMMA in this pyramid relative to each other and Figure 2 provides an overview of the different combinations of styrenics and PMMA. Table 1 compares selected properties of PS, SAN, ABS, ASA, AES, and PMMA.

| |

| Figure 1: plastics performance pyramid containing PS, SAN, ABS, and PMMA. |

|

| Figure 2: overview of styrene polymers from base polymer to impact modification. |

|

| Table 1: property comparison of GPPS, SAN, PMMA, ABS, ASA, and AES. |

Design properties for part design: weatherability and UV resistance of PMMA, ABS, and ASA

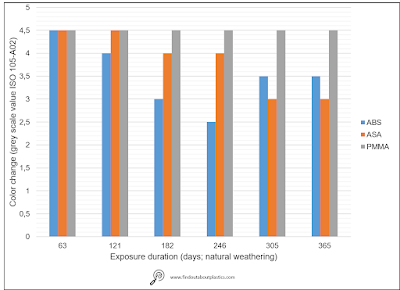

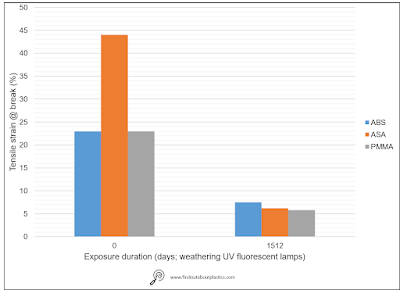

Mrs. Fatma Filiz Yildirim [4] investigated with her team the weathering methods on the properties of the ABS, ASA and PMMA. Testing was done by exposing the plastic parts to natural weathering, Xenon-arc lamp, and UV fluorescent lamps for a certain period of time and then analyzed by grey scale (ISO 105-A02; 5 = low color change; 1 = high color change). Also, tensile strength was measured after exposure to natural weathering, Xenon-arc lamp, and UV fluorescent lamp. Figure 3, 4, and 5 show the results of the weathering study. The results indicate that PMMA has the best performance in all three weathering conditions. The xenon-arc lamp weathering method resulted in the lowest grey scale values for ABS and weathering by UV fluorescent lamps lead to the lowest grey scale with ASA samples. Reason for the change is the butadiene monomer containing double bonds which are broken up. This can be seen in the tensile strain values which change (materials harden and become brittle), whereas the tensile stress levels remain mostly at the same level for all three materials (Figure 6 and Figure 7). Using AES instead of ABS will allow you to have good high impact resistance (even at low temperatures) and UV resistance since the limitation by butadiene rubber is eliminated.

|

| Figure 3: color change (grey scale) of ABS, ASA, and PMMA in natural weathering conditions [4]. |

|

| Figure 4: color change (grey scale) of ABS, ASA, and PMMA as a result of weathering by Xenon-arc lamp [4]. |

|

| Figure 5: color change (grey scale) of ABS, ASA, and PMMA as a result of weathering by UV lamp [4]. |

|

| Figure 6: change of tensile stress @ break after weathering with UV lamp of ABS, ASA, and PMMA [4]. |

|

| Figure 7: change of tensile strain after weathering with UV lamp of ABS, ASA, and PMMA [4]. |

|

| Figure 8: relative property comparison of SAN, PMMA, ABS, ASA, and AES. |

|

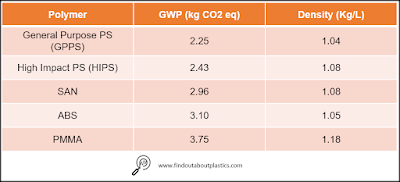

| Table 2: comparison Global Warming Potential (GWP) of PS, SAN, ABS, and PMMA [9]. |

Thanks for reading and #findoutaboutplastics!

Greetings

Herwig Juster

Interested to talk with me about your polymer material selection, sustainability, and part design needs - here you can contact me

Interested in my monthly blog posts – then subscribe here and receive my high performance polymers knowledge matrix.