Hello and welcome back to another post on design properties for polymer engineers. Today’s session is dedicated to the high performance polymer PolyArylAmide (PARA or MXD6 or PAMXD6). Knowing about such a polymer can be an advantage during your next polymer material selection project, especially when dealing with high strength, stiffness, and cosmetic good appearance applications.

Introduction and structure - What are Polyarylamides?

Polyarylamides belong to the group of semi-aromatic Polyamides and have a glass transition point (Tg) of 85°C and a melting point of 235°C, and melt temperature of 280°C. They combine several interesting properties:

-Lowest moisture uptake among aliphatic and semi-aromatic Polyamides

-High dimensional stability enabling complex parts

-Excellent surface appearance - “best-in-class” among the Polyamides

-Outstanding stiffened and strength

-Very good flowability which allows moulding of thin walls down to 0.5 mm and also for thicker walls without sinkmarks

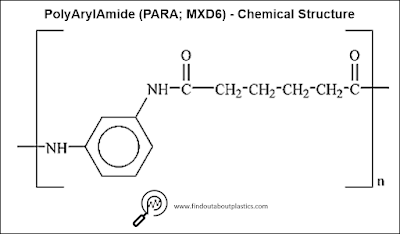

Figure 1 shows the chemical composition of the PARA repetition unit and Figure 2 shows the DMA curve of a 60 wt% glass-fiber reinforced PARA (in comparison to PA 6.12- GF 60 wt%). It can be seen that up to the glass transition point, high modulus values of 18 GPa can be achieved followed by a decrease to a level of 10 GPa at 130°C. Long-chain aliphatic PA 6.12 can keep the high modulus of 16 GPa until 40°C and then the decrease takes place. Furthermore, it can be seen that PARA is not a typical high heat thermoplastic, it is more a high performance plastic, combining the aforementioned key characteristics.

|

| Figure 1: chemical structure of PolyArylAmide (PARA; MXD6). |

|

| Figure 2: DMA curve of a 60 wt% glass-fiber reinforced PARA in comparison to PA 6.12- GF 60 wt%. |

Characteristic properties of PARA

Let us circle back to the low moisture uptake. Comparing the moisture absorption of PARA, PPA, and standard aliphatic Polyamides, it can be shown that 50 wt% glass fiber reinforced PARA changes only 0.32% after 24-hour water immersion (at 23°C), whereas other semi-aromatic polyamides change twice and standard polyamides four times as much compared to the PARA value.

Apart from the low water uptake, PARA offers the best surface among all Polyamides due to its fine crystallization in the surface regions. This makes it a good choice for coating or painting applications. Moulded parts in glass-fiber reinforced PARA achieve a low surface roughness value of 0.10 mu Ra and standard Polyamides are around 0.25 mu. Mechanically polished steel has the equivalent surface roughness value as PARA. Among the Polyamides (aliphatic and semi-aromatic), PARA has the lowest surface roughness value. Reason is the fine crystallization of PARA in the surface layers of a moulded part.

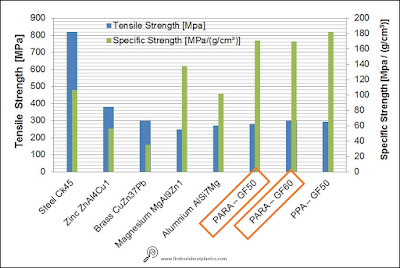

The high stiffness and strength of PARA results from the fairly large molecule with its aromatic ring structures which entangle, together with glass fiber reinforcement. Table 1 compares mechanical properties of PARA to die casting metals. The mechanical performance of PARA favours it for metal replacement of applications which need high strength and excellent surface appearance.

Table 1: Overview mechanical properties of Polyarylamide (PARA) compared to die-casting metals.

| Properties | PARA-GF 50 wt% | PARA-GF 60 wt% | AG6 (Al) | AS9U3 (Al) | ZAMAK (Zn) | AZ91D (Mg) |

|---|---|---|---|---|---|---|

| Density (g/cm3) | 1.64 | 1.77 | 2.7 | 2.9 | 6.6 | 1.83 |

| Melting temperature (°C) | 235 | 235 | 660 | 660 | 390 | 470 |

| Tensile strength (MPa) | 280 | 280 | 220 | 200 | 280 | 235 |

| E-Modulus (GPa) | 20 | 23 | 65 | 72 | 85 | 45 |

| Elongation at break (%) | 1.7 | 1.8 | 0.2 | 0.2 | 0.2 | 3.0 |

|

| Figure 3: comparison specific strength of PARA with glass fiber reinforcement to die-casting metals. |

|

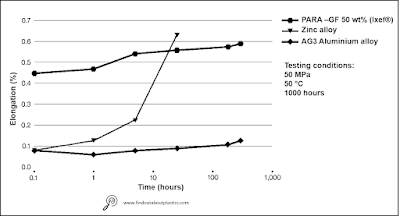

| Figure 4: comparison creep resistance of glass fiber reinforced PARA to Zinc and Alumnium alloys [1]. |

Table 2: Coefficient of Linear Thermal Expansion (CLTE) of Polyarylamide (PARA) compared to die-casting metals.

| CLTE (10-5 K-1) | PARA-GF 50 wt% (flow direction) | PARA-GF 50 wt% (transverse direction) | Aluminium | Brass | Zinc | Steel |

|---|---|---|---|---|---|---|

| / | 1.5 | 3.6 | 2.4 | 1.8 | 3 | 1.2 |

|

| Figure 5: spiral flow results of PARA- GF 50 wt% in comparison to PPS and PA 6. |

Table 3: Main producers of PARA and commercial compounds.

| Manufacturer | Commercial Name |

|---|---|

| Solvay | Ixef® |

| Mitsubishi Engineering Plastics, MGC | Reny® |

| Akro Compounds | AKROLOY®PARA |

| TER Plastics | TEREZ®GT2 |

Interested in our material solutions - check out our product page here

Interested to talk with me about your polymer material selection, sustainability, and part design needs - here you can contact me

Interested in my monthly blog posts – then subscribe here and receive my high performance polymers knowledge matrix.

[1] https://www.solvay.com/en/brands/ixef-para/properties

[2] https://akro-plastic.com/compound-overview/akroloy-pa-para/

[3] https://www.findoutaboutplastics.com/2023/04/polyarylamide-vs-polyamide-para-vs-pa.html

[4] https://www.findoutaboutplastics.com/2021/12/overcoming-automotive-challenges-in.html

[5] https://www.findoutaboutplastics.com/2020/10/strategic-sales-and-marketing-in.html

No comments:

Post a Comment